Part II: Field Test Kit Methods

A Recap of the EPA-HUD Joint Workshop on Lead-Based Paint

On November 1 and 2, 2023, the U.S. Environmental Protection Agency (EPA) and U.S. Department of Housing and Urban Development (HUD) held a virtual technical workshop to hear from experts on specific topics such as the relationship between LBP and dust-lead and an update of existing and emerging technologies for detection, measurement, and characterization of low levels of lead in paint. This follows a Court order directing EPA to reconsider the legal definition of Lead-Based Paint (1.0 mg/cm2 and 0.5%).

I have divided the presentations into three categories:

- Detection of Lead by Hand-held Fluorescence Instruments (XRF) (Part I)

- Detection of Lead by Chemical Field Screening Tools (“Test Kits”) (Part II)

- Supplemental Information and Emerging Technologies (Part III)

This article covers the presentations pertaining to chemical test kits used for lead detection. For a review of the other presentations (Parts I and III of this three part series), refer to the links to the pages above.

The workshop presentations and subsequent public comments will be used to update the LBP standard definition. The public comment period is open and comments can be submitted via the EPA online docket until December 31, 2023.

This entire process is expected to take about three to four years.

The following is an overview and my summary of the speakers and the information I thought was most helpful to the goal of the workshop (presentation titles were shortened for brevity).

Assessing Lead Test Kit Performance on Determining LBP, Dr. Bob Lordo, Batelle Institute

Dr. Lordo was involved in the validation of the now discontinued 3M LeadCheck swabs. The swabs are based on the reaction of sodium rhodizonate to lead, forming a red-colored complex. He provided an overview of the past testing validation process, which involved testing against the two main types of lead in paint, white lead carbonate and yellow lead chromate, with various field test kits. None of the candidate test kit strips could be validated against the 95% confidence level against false positives or false negatives. However, the 3M swabs were able to achieve a 95% accuracy rate with regards to false negatives and therefore were given conditional approval by EPA based on the need driven by the RRP Renovator prescribed practices.

The 3M swabs provide a color change of pink to red, giving a semi-quantitative measure of the lead present based on the shade of the color. The reagent substance is very reactive to lead but it depends on the user being able to expose all layers, which can sometimes be difficult for multi-layer samples. Some false positives are unavoidable as the chemistry of certain metals in paint pigments such as antimony and barium will result in the formation of a red-colored complex. They are currently seeking a new manufacturer for the test swabs as there is still a big need for them.

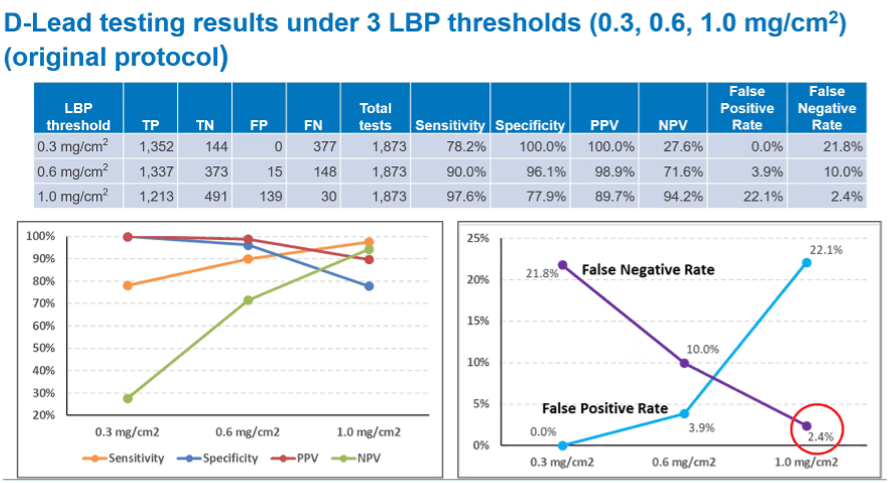

The more cumbersome and slower D-Lead screening procedure was also approved for RRP use based on meeting the low false negative criteria. This method involves soaking a paint chip in a test reagent and then waiting for a color change, which can be compared against visual comparison samples. The remainder of his presentation was based on whether the D-Lead screening kits could be validated for a lower LBP standard. This test kit is based on a color change of hues of browns where a tan color is generally interpreted as lead-containing and brown color represents LBP.

A graphic summary of the D-Lead testing against the proposed lower 0.3 mg/cm2 and 0.6 mg/cm2 standards is summarized below:

It was concluded that the D-Lead kit does not meet the more critical false negative criteria for the 0.3 or 0.6 mg/cm2 standard. Based on an interpolation of the data presented above, it does appear D-Lead could potentially be validated for close to a 95% false negative rate for a 0.75 mg/cm2 LBP Standard with some slight improvements in the method. There is an exceedingly large false negative rate to overcome at 0.6 and lower levels.

Author commentary: 3M suspended the production and sale of LeadCheck™ test kits in October 2023. As of this writing, EPA has not released any updated guidance and therefore it appears that they expect contractors to use the more cumbersome D-Lead kits for compliance (or XRF or paint chip analyses). So far, I have not received any calls from contractors or homeowners requesting XRF testing in lieu of using testing swabs. Homeowners may choose to use the widely available unapproved swabs for their own purposes.

Direct Environmental Lead Detection by Luminescence Using Perovskite Fluorescence, Lukas Helmbrecht, Lumetallix

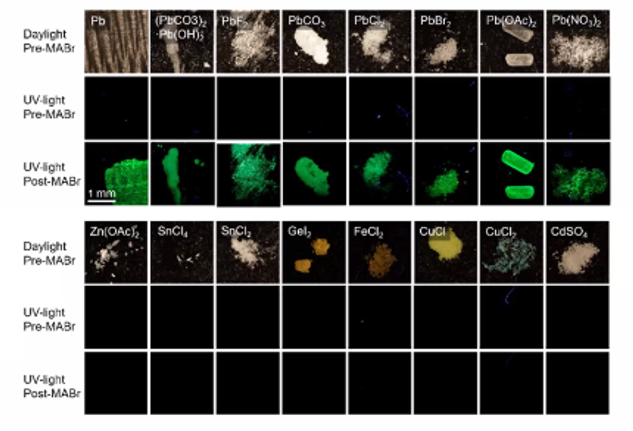

A new field screening technology is possible based on the efficient reaction of an ammonium halide-based reagent that converts all forms of lead to lead perovskite, a mineral which can be observed by its visible spectrum fluorescence. This chemistry is well-known and many consumer products such as solar cells and some LED lights (not the common strip lights) take advantage of the fluorescing property of this species of lead. In addition, other metals that may be present in paint do not similarly react, making false negatives unlikely. The following illustrates the fluorescence of the various species (salts) of lead and the absence of reactive fluorescence from several common heavy metals found in paints:

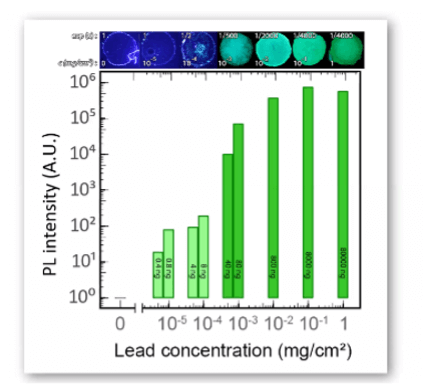

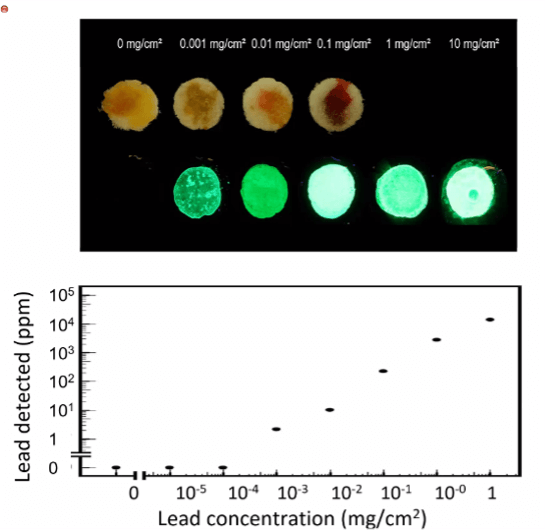

The figures below illustrate the sensitivity for each order of magnitude under optimized conditions, potentially reaching nanogram sensitivity in some circumstances.

For the examples above, a sensitivity was achieved of approximately 0.001 mg/cm2, equating to an approximate 2 ppm detection limit. This is approximately 1000x more sensitive than the sodium rhodizonate-based swabs (LeadCheck et. al.).

The density of paint is a limitation of the sensitivity, as the reagent is not effective in penetrating layers.

This research led to the development of a new type of lead test kit, branded as Lumetallix.

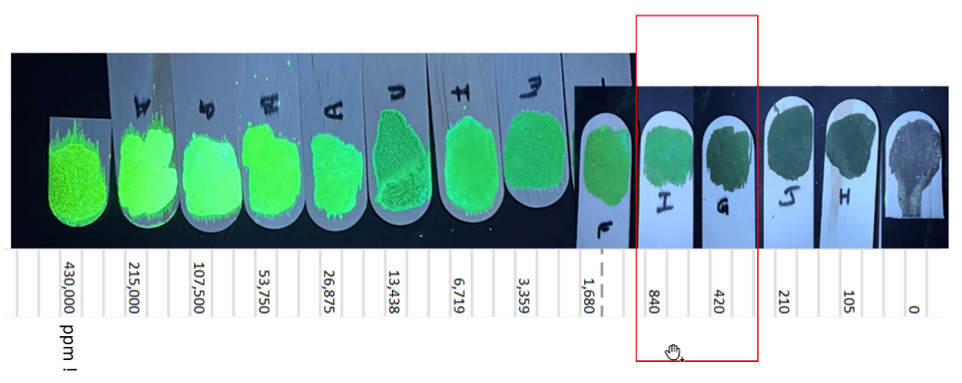

The company’s researchers were able to obtain a lead-based paint sold in the Ivory Coast to determine the sensitivity for a single layer of paint that was subsequently diluted. Based on this study, it appeared that the detection limit (threshold for a fluorescing color change) was about 500 ppm, shown in the figure below.

(Author comment: Based on the estimated equivalences established to a previous presenter, this sensitivity would roughly equate to 0.05 mg/cm2.)

Remarkably, their testing methods have been able to yield fluorescing results for a variety of highly stable forms of lead including leaded glassware and lead glazed dishware. In these cases however, the surfaces need to be etched with fine sandpaper or another recommended abrasive.

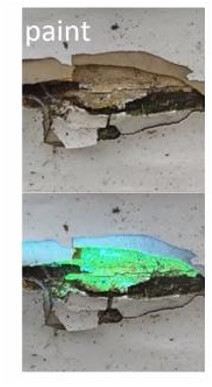

Two of the more novel applications of this technology would be to identify the relative lead levels of different paint layers or trace the foot tracking of lead dust on the floors.

They have noted that the reagent is potentially a mild irritant not approved for use on the skin but some employees of their firm have tried it with no adverse effects.

The associated research papers, “Comparing Lead-Based Paint Detection using Perovskite and X-Ray Fluorescence” (Alexander van Geen, Lukas Helmbrecht et. al.) and Direct Environmental Lead Detection by Photoluminescent Perovskite Formation with Nanogram Sensitivity (Lukas Helmbrecht, S.W. van Dongen et. al.) are currently at the time of this writing under pre-print review for publication by the American Chemical Society publication Environmental Science and Technology magazine.

Author commentary: The unapproved Lumetallix test kits are currently available online for $75 for an estimated 100 tests. No online reviews have been found and a Safety Data Sheet for the reagent has not been published. It would appear that the reagent is a dilute solution of methylammonium bromide in isopropyl alcohol.

Possible applications include field cleaning personnel being able to check surfaces after hazard control cleaning activities have been performed to assess whether clearance dust wipe sampling is likely to yield passing results. This could also potentially be useful for field delineation of lead dust contamination. For example, when an LBP hazard source is found to have resulted in a dispersed floor dust hazard, it could be useful to check the lead dust levels at intervals on the floors throughout the building to determine what extent the lead dust has been tracked to require cleaning. This method would be much less sensitive on greenish-colored substrates.

Methylammonium iodide is similarly reactive, forming a red-fluorescing substance, albeit slightly less visible under ultraviolet light. It would not be surprising to see a competing manufacturer produce a similar product, adapting the “Red Means Lead” trademark.

This field kit will be helpful to homeowners interested in identifying leaded glass or dishware or toys. However, users will need help interpreting the results when they find lead on window sills or floors.

Tri-Tech is currently conducting a field trial for the application of this screening method to identify lead dust contamination on hard floors and others surfaces and gain some experience observing fluorescence intensity and the corresponding laboratory result. Watch for a future article to be published of the findings. Tri-Tech expects to use this test kit methodology in the future for rapid identification of lead dust for Lead Risk Assessments and lead dust contamination investigations.

Prevalence of U.S. Homes with Lower Lead Levels and Associated Lead Hazards and Review of RRP “White-glove Tests” for Cleaning Verification at Lower Levels ; Dr. Gary Dewalt, QuanTech

Based on Healthy Home survey data, LBP is estimated to be present in about 6% of post-1977 housing units. However, this includes identification of lead glazed ceramic (in about 5% of the homes) and also likely includes false positives (from the Viken XRF). Non ceramic related LBP was all identified in 2000 or older housing and was expected to include salvaged materials/paints or the use of specialty leaded paints. Notwithstanding these circumstances, the likelihood of true LBP present in post-1977 housing is believed to be extremely remote.

The second part of his presentation consisted of his review of studies of the impact of a lower lead standard on RRP procedures. RRP includes a visual self-clearance step based on the absence of visible dust. In some circumstances such as an ordinary renovation, this visual clearance will be the final step and in other circumstances (such as regulated hazard control or abatement projects), the work area will be assessed by follow up dust testing. Based on these preliminary studies, it was concluded that these tests perform well at existing and lower thresholds for “cleanable surfaces” but not “irregular surfaces” (cracked, pitted, semi-porous surfaces etc.) . However, there is not practical way of gauging how cleanable a surface is. It is expected unsurprisingly that lowering the action level is likely to result in more clearance failures.

***

Part III of this article comprises presentations including Supplemental Information and Emerging Technologies not directly associated with the detection of lead paint.

Return to Part I of this article (XRF Technology.)