A Recap of the EPA-HUD Workshop on Lead-Based Paint

Part I: Detection of Lead by Hand-Held X-Ray fluorescence Instruments (XRF)

Except for the changes in lead dust standards, the lead testing and abatement industry has seen notably few updates and changes to testing procedures and related activities since the lead paint regulations were ramped up following the US Environmental Protection Agency RRP rulemaking in 2008. Indeed, the XRF measurement technology hasn’t changed much since its inception in 1987. Updated industry guidance from HUD seems overdue as it has not updated its guidelines since 2012.

Now an action from the Courts seems to have accelerated the pace of change. A 2021 9th Circuit Court of Appeals opinion, A Community Voice, Sierra Club et. al. vs. EPA, required EPA to consider adopting more stringent lead cleanup standards, including those for lead dust, lead levels in paint and lead in soil. The petitioners in this case were not satisfied with the 2019 changes in dust standards. In an extraordinary measure, the Court also remanded EPA to reconsider the paint and soil standards even though these changes were not sought by the litigation. The litigation did not involve HUD or its guidelines. However, the reconsideration of these standards necessarily involves HUD since HUD largely defers to the EPA standards and guidance. There is a practical necessity to harmonize the lead standards pertaining to child-occupied properties under the authority of EPA and the target housing under the authority of HUD.

Will the 2019 Standards Bite the Dust?

In August of 2023, EPA published a Notice of Proposed Rulemaking, Reconsideration of the Dust-Lead Hazard Standards and Dust Lead Post-Abatement Clearance Levels. Public comment was sought as part of this re-evaluation of the 2019 lead dust standards, which the Court opinion claimed were not low enough to meet Congressional intent. The comment period closed on October 2, 2023. The additional Rulemaking is expected in the Fall of 2024. You can find a recap of this in a previous article.

Experts Paint a New Picture

The second step was the re-evaluation of the definition of lead-based paint. On November 1 and 2, 2023, the U.S. Environmental Protection Agency (EPA) and U.S. Department of Housing and Urban Development (HUD) held a virtual technical workshop to hear from experts on specific topics such as the relationship between LBP and dust-lead and an update of existing and emerging technologies for detection, measurement, and characterization of low levels of lead in paint. The following is an overview and my summary of the speakers and the information I thought was most helpful to the goal of the workshop (presentation titles were shortened for brevity). I have divided the presentations into three categories:

- Detection of Lead by Hand-held Fluorescence Instruments (XRF)-Part I

- Detection of Lead by Chemical Field Screening Tools (“Test Kits”)– Part II

- Supplemental Information and Emerging Technologies– Part III

The remainder of this article covers the presentations pertaining to using XRF technology for lead detection. For a review of the other presentations (Parts II and III of this three part series), refer to the links to the pages above.

Without intending to diminish their contributions to the lead hazard control field, I have omitted the review of three additional presenters who presented information that was not directly related to the consideration of the lowering of the paint standard definition. In addition, I was unable to participate in the session by Dr. Anne Steenhout of the University of Brussels pertaining to evidence from environmental epidemiology and biokinetic modeling. Time allowing, I will review their contributions in a future article.

The workshop presentation information as well as public comments will be used to change or reaffirm the LBP standard definition. The public comments will be received on the EPA online docket until December 31, 2023.

After the initial evaluation is complete, a proposed rulemaking with be published and an initial comment period will be established. After consideration of that additional information, a final Rule when then be published. This entire process is expected to take about three to four years.

An EPA summary of the presentations is expected to be published online in a few months.

The remainder of this article summarizes the presentations pertaining to lead detection by XRF.

Developing Performance Characteristic Sheets (PCS) at <1 mg/cm2; Dr. David Cox, QuanTech

Dr. Cox provided an overview of the PCS process, which is used to validate XRF instruments for LBP testing for EPA and HUD compliance purposes. This involves testing two separate instruments against an archive of building component standards where the levels of lead in the paint have been rigorously tested by ICP laboratory methods. These standards acquired from samples from old housing components include real-world effects including spatial variability (16% of standard samples have large spatial variability) and a large number of paint layers (most between 7 and 20 layers). The standard archive was also used to validate the field check swabs (the now discontinued 3M Lead Check brand). He noted that the original PCS protocol was designed as an interim measure, but was never updated as intended.

Based on their preliminary studies, it appears that the two leading XRF instruments (Viken Cobalt-source and SciAps X-ray tube) could likely be validated for lower levels such as 0.5 or 0.7 mg/cm2. It remains to be seen how the less common Niton Xlp and RMD LPA-1 units that were not evaluated would perform at these lower levels.

Both the Viken and SciAps would potentially have narrow inconclusive ranges, depending on where the new threshold is established. The inconclusive range to counter the potential circumstance of a false negative is determined where a 95% statistical confidence is not achieved for a determination of “positive” or “negative.” However, this is not for the threshold value itself but double the threshold value. There are also inconclusive ranges similarly determined at half the threshold to attempt to avoid the lesser concerning case of false positives.

The cost of a PCS study is typically less than the cost of two XRF instruments and therefore should not be seen as a barrier to getting more XRF units approved for use.

Measurements closer to the action level tend to be longer. (Author’s commentary: A lower LBP standard would increase testing time and therefore likely increase testing costs).

While the LBP area (1.0 mg/cm2) and percent weight (5000 ppm/0.5%) standards are not directly comparable, evaluating large data sets (where both measurements are made on the same sample) can demonstrate a generalized indirect empirical relationship between the two standards. On average, the 1.0 mg/cm2 corresponds more closely (by a very convenient coincidence!) to 10,000 ppm/1%.

(Author’s commentary: If the LBP area threshold measurement is lowered, the corresponding by percent weight should not be lowered proportionately as much as the percent weight value standard is relatively more stringent. However, a counter argument might be that since the percent weight basis is subject to dilution from overlying layers whereas the area measurement is not, it might be suitable to keep the percent weight standard as more stringent).

A subsequent presenter cast some doubt about the suitability of the PCS sample archive to adequately validate X-ray based L-shell XRF units based on the potential lack of a signal penetration for deeply buried lead and the possibility for titanium and zinc interferences. Notwithstanding acknowledging that there is variability and a small allowable margin of error, Dr. Cox did not affirm these concerns from his experience.

Their American Healthy Homes Survey conducted by HUD in 2005-6 of over a thousand homes provides a helpful broad characterization of the extent of lead paint in older housing. An additional study of 703 additional homes in a second American Health Homes Survey of 703 homes conducted by QuanTech in 2018-2019 had similar findings concerning lead paint.

A summary of the results of these surveys was provided by another speaker later in the program.

Analysis of Lead-Based Paint 0.1 – 0.3 mg/cm2 by X-Ray Tube XRF | Brendan

Connors, SciAps

Mr. Connors is the Chief Scientist of SciAps, one of the two leading manufacturers of XRF instrumentation of hand-held lead (and other metals testing) field screening devices. They have obtained PCS approval for their relatively new X-ray tube based device, the X-550.

This XRF works by providing broadband X-ray emissions (differing energies and intensities) to excite the L-shell alpha, beta and gamma electrons of lead and other heavy atoms. This unit utilizes a new Silicon Drift detector developed about ten years ago with higher intensity, better peak resolution, better signal to noise ratio (equates to better sensitivity) and shorter test times. A beam filter can optimize the emissions for specific applications (e.g. measurement in paint versus in soil or consumer products). The relative measurements of the three peaks can also be used to determine an estimated depth factor for buried lead. There are two instrument options, rhodium and gold anode x-ray tubes, which may have slightly different performance depending on action level. For example, the rhodium anode tube offers threshold screening at a 0.5 mg/cm2 action level. Neither option offers much of an intrinsic sensitivity advantage, but there are small differences in performance (e.g. threshold vs. inconclusive range) depending on action level. (Author commentary: If you are going to buy one in the future, the ideal anode will depend on what the action level is—so hold off on your purchase if you can until this question is settled.)

They commissioned QuanTech to conduct PCS testing at the 0.3 and 0.1 mg/cm2 levels and obtained successful validation using the gold anode model for these limits (given a narrow inconclusive range). The detection limit for surface lead can be as low as about 1-3 ug/cm2 depending on the substrate. (Author’s commentary: This advanced sensitivity would have no use for LBP testing but could be useful in developing a test method for the screening of lead levels in dust wipes).

They have not observed any performance limitations for their unit from signal attenuation when compared to the higher energy K-shell XRFs for real world samples. They have also not observed real-world cases where a K-shell XRF detected levels of lead in excess of the action level but the X-550 L-shell unit missed it entirely.

Reducing the LBP standard below 0.3 mg/cm2 at this time is problematic because there is no NIST standard readily available for sale at levels below 0.3 mg/cm2.

XRF Analyzer Performance Dynamics and Outdated PCS Certification Procedures, Peter Rothschild & James Ryan, Viken Detection

Mssrs. Rothschild and Ryan are the Principals of the other leading manufacturer of hand-held XRF lead (and other metals testing) field screening device, the Viken Pb200i. They have obtained PCS approval for their relatively new cobalt-sourced device. This XRF works by providing X-ray emissions to excite the K-shell electrons of lead and other heavy atoms.

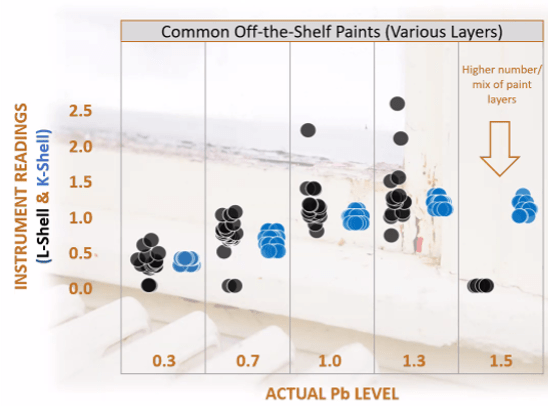

Based on their internal testing, they believe that K-shell based units are superior to L-shell units. This is based on the stronger signal strength and that L-shell measurement results in increasing errors when measuring at lower levels. They believe that their unit outperforms L-shell based units and that the PCS standard archive is outdated, in part because the standards do not include the additional layers of paint added and account for the various paint mixtures that have come on the market, including titanium and zinc-containing paints that could potentially attenuate the signal of competing L-shell units.

They recommended the updating of the PCS sample archive prior to the re-certification of XRF units for any lower levels and to make sure that representative samples are included with titanium and zinc-containing paint formulations.

Author’s commentary: There is some debate and question about what XRF units are best, primarily hinging on how a specific radioactive source metal or X-ray source works at various energy levels. It is generally understood that X-ray tube L-shell units are faster and more accurate than K-shell units at lower levels and L-shell units can provide faster readings at some high levels depending on depth and sample density. A stronger K-shell source can penetrate deeper and has less difficulty with other interfering and attenuating metals in a sample. X-ray tube devices can suffer false positives on certain thin, hollow or unusual substrates. However, legacy L-shell units (such as the Innov-X Alpha XRF) readily identify these suspected false positives with a unique “>1.0 mg/cm2” reading. In addition, when multiple layers of lead are present the algorithms attempt to compensate for the possibility that the lower level(s) of lead has not been sufficiently excited returning a “>” than reading. However, in my experience sometimes the algorithm overcompensates and it appears that the true value for readings of >1.01 to >1.30 reflect true lower levels in the range of 0.5-0.9 (the PCS warns only of 1.01-1.1 as inconclusive readings).

Real-world comparisons between X-ray and source based units are difficult as it is rare for two different XRF to be used on the same housing. Tri-Tech has two anecdotal examples where large apartment projects were tested by two different units. On one project when an X-ray tube device was paired with an RMD LPA-1 cobalt source, the latter tended to have higher readings for painted radiators. On the other project, the X-ray tube unit had higher readings for stair risers and tread (including where overlying rubber tread was present) than the Niton cadmium sourced XRF. For more information on XRF false positives and false negatives, refer to the article Are You Really Sure You Have Lead Paint?

Anecdotally, I have seen the Niton XLp XRF (K+L shell) identify false positives associated with lead within concrete (galvanized coating on the rebar?) or on drywall (electrical wire insulation behind?), a consequence of a too strong signal picking up deeply embedded lead from or behind a substrate. A too strong XRF signal will potentially also add to the measurement paint detected on the opposite side as can happen with two-sided painted components such as doors, window sashes and panes and radiator fins.

The simple answer is that different XRF models excel in different circumstances—in some cases a stronger energy signal is desirable, in some it is not.

Association Between Paint Lead and Dust Lead in the American Healthy Housing Survey: Assessing Different Paint Lead Definitions below 1.0 mg/cm2 to Predict Household Dust Lead Levels, Jonathan Wilson, National Center for Healthy Housing

This presentation was perhaps the one that most directly addressed the question of how lowering the definition would affect the identification of lead hazards and advance the goal of more “lead-safe housing.” It was a highly technical presentation based largely on modeling from National Healthy Housing survey data. They ran multi-variable models on the 1.0 mg/cm2 and lower proposed standards to see if the lower LBP definitions were more predictive of finding lead dust hazards. They concluded that the 1.0 mg/cm2 performed just as well as lower standards. On this basis, the lowering of the standard could not be justified. However, in the open discussion the obvious point was made by another panelist—if you look for more problems you will find more problems.

(Author’s commentary: My personal interpretation is that this demonstrates maintenance and housekeeping/ cleaning practices are far more important variables than lead levels in paint. Its not difficult to construct hypothetical scenarios that show the opposite effect. For example, larger and older and more historic and valuable homes will tend to have higher levels of lead in paint because better grades of paint with more lead content were likely used. Some original architectural components will be retained based on their character rather than being replaced. Based on the value of the home and the inherent pride of home ownership, better maintenance and cleaning practices were used. It also may be argued that lead content imparts some durability and moisture resistance compared to paint with lower levels of lead,. In contrast, lower value housing is often converted for rental property usage. In these homes, lower grade paints were used (typically with lower levels of lead) and “diluted” by many more layers of paint. This type of housing is typically less well maintained and cleaned less frequently and therefore is more likely to contain lead dust hazards from neglect.)

Analysis of Lead in Children’s Products using XRF, Rick Uhl, Chief Chemist, U.S. Consumer Product Safety Commission

Mr. Uhl presented an overview of the current state of CPSC testing for lead in consumer goods, whose limits currently stand at 100 ppm for children’s products and 0.009% (90 ppm) for paint and similar surface coatings in furniture and children’s products. He noted that High Definition XRF (HDXRF) is a useful tool for differentiating lead in surface coating from lead in substrate, with an analysis time of about 5 minutes per sample. However, an HDXRF model tailored for the rapid analysis of consumer products nor a hand-held model for paint inspection is available at this time.

(Author commentary: Strictly speaking, this presentation was not within the scope of lead in building materials, the focus of this conference. However, it is helpful for lead professionals to know that CPSC continues to diligently monitor for lead from non-building related sources. These background sources cannot always be differentiated from building-related exposures. Also, it is important to know what gains are possible associated with reducing lead exposures in consumer products when considering ways to reduce lead exposure from building sources. Ideally, the risk tolerances would be harmonized between building and consumer product related exposures.)

My review of the field test kit-related presentations continues in Part III of this article.